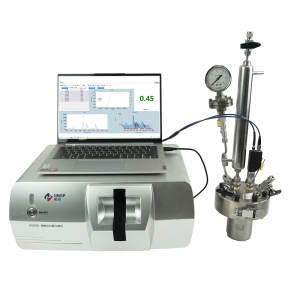

IT2000CE Online FT-IR Analyzer

• Highly applicable:

§ Capability to measure black or deep color samples, without the influence from sample color;

§ Capability to detect liquid components in suspension, getting rid of the interference from solid particles;

§ Resistant to high temperature and pressure, strong acid/alkali, and strong corrosive liquid.

• Fast: Data acquired in seconds

• Intuitive: Real-time display of the dynamic change of reactants and products

• Multi-functional: Simultaneous measurement of the concentrations of multiple components

• Intelligent: Automatic analysis of FT-IR spectra based on intelligent algorithm

Real-time monitoring of the changes of multiple components

| Flow cell | Immersion probe | |

| Application mode | ||

| Unit dimensions | 51 cm (Length) × 30 cm (Width) × 25 cm (Height) | |

| Weight | ≤15 kg | |

| Resolution | 2 cm-1, 4 cm-1, or 8 cm-1 | |

| Sample suitability | Strong acid/alkali and strong corrosive liquid samples can be analyzed | |

| Display screen | 10.5’’ capacitive touchscreen, supporting multi-point touch and multi-angle folding | |

| Spectral range | 500 ~ 5000 cm-1 | 600 ~ 1800 cm-1 |

| Sample temperature | –50 ~ 100 ºC | –150 ~ 230 ºC |

| Sample pressure | ≤2 MPa | ≤10 MPa |

| Length of optical fiber | – | 1.5 m or 3 m |

| Connector Interface/Probe dimensions | Φ6 as standard, 1/8’’ or 1/4‘’ upon request (steel tubing using tube fittings, or hose using barbed fittings) | L: 300 mm, D: 6.35 mm (Hastelloy alloy)L: 150 mm, D: 6.35 mm (PEEK) |

| Material | C276 alloy as standard, 316 stainless steel, 304 stainless steel, Monel alloy or TA2 upon request | Hastelloy alloy as standard, PEEK upon request |

Multiple absorption peaks of target components can be marked while IR spectra being collected. The change of the marked components is displayed in real time.

The embedded quantification model can be used to monitor component concentration in chemical reactions in real time.

Brochure - IT2000CE online FT-IR analyzer (English version)

Brochure - IT2000CE online FT-IR analyzer (Russian version)