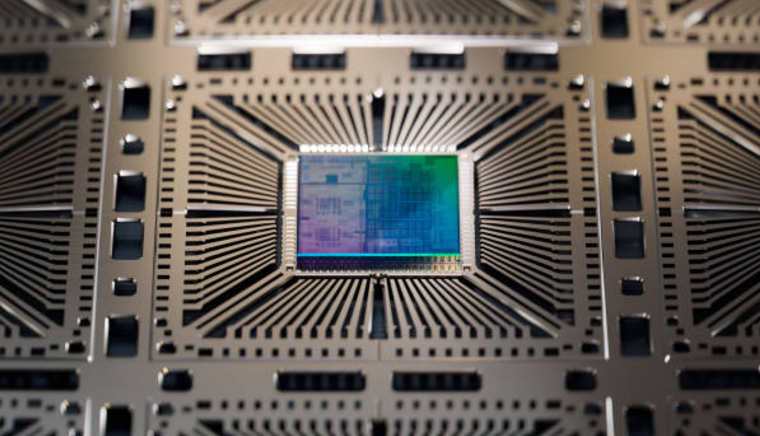

Fiber Optic Spectrometer: A Revolutionary Tool in Semiconductor Innovation and Application

The semiconductor industry, as the cornerstone of modern information technology, consistently attracts global attention. In this context, the fiber optic spectrometer, with its efficient and precise spectral analysis capabilities, has found increasingly broad applications in the semiconductor field. Its ingenious working principle involves using optical fibers to channel light into the spectrometer. Through components like gratings, slits, and detectors, it disperses and focuses light of different wavelengths, converting optical signals into electrical signals and presenting them as intuitive spectral graphs.

1 Fiber Optic Spectrometers in Semiconductor Applications

● Material Analysis

In semiconductor material testing, the fiber optic spectrometer plays an irreplaceable role. By accurately measuring optical properties like absorption, reflection, and transmission spectra, it comprehensively evaluates material quality and performance. Particularly in the development of compound semiconductors, it precisely determines parameters such as refractive index and absorption coefficient, providing scientific guidance for material optimization and selection.

● Process Control

The fiber optic spectrometer is equally critical in semiconductor manufacturing process control. By monitoring key parameters such as temperature, pressure, and gas composition in real-time, it helps engineers adjust conditions promptly, ensuring stable and controlled production processes. Additionally, it detects defects and impurities in semiconductor devices, significantly enhancing product quality and reliability.

● Plasma Technology Monitoring

Plasma technology is widely used in processes like etching and deposition. The fiber optic spectrometer enables real-time monitoring of emission intensity and wavelength distribution in plasmas, providing precise data for process control. By tracking plasma parameter changes, it ensures precise control over etch depth and deposition rates, improving device performance and consistency.

● UV Curing in Packaging

In semiconductor packaging, UV curing is commonly used for solidifying resin materials. Fiber optic spectrometers measure UV intensity and wavelength changes during curing, ensuring optimal effects and product quality. By monitoring the stability and consistency of UV light sources, they identify and rectify curing issues promptly, improving production efficiency and product reliability.

2 Advantages of Fiber Optic Spectrometers

● High Precision

The spectrometer’s high resolution and sensitivity enable precise measurement of optical properties and process parameters, surpassing traditional methods.

● Real-time Monitoring

It provides immediate feedback on process parameters, aiding engineers in identifying and resolving issues efficiently, thus enhancing productivity and quality.

● Non-contact Measurement

This approach avoids material damage or contamination, preserving integrity and performance while boosting reliability and durability.

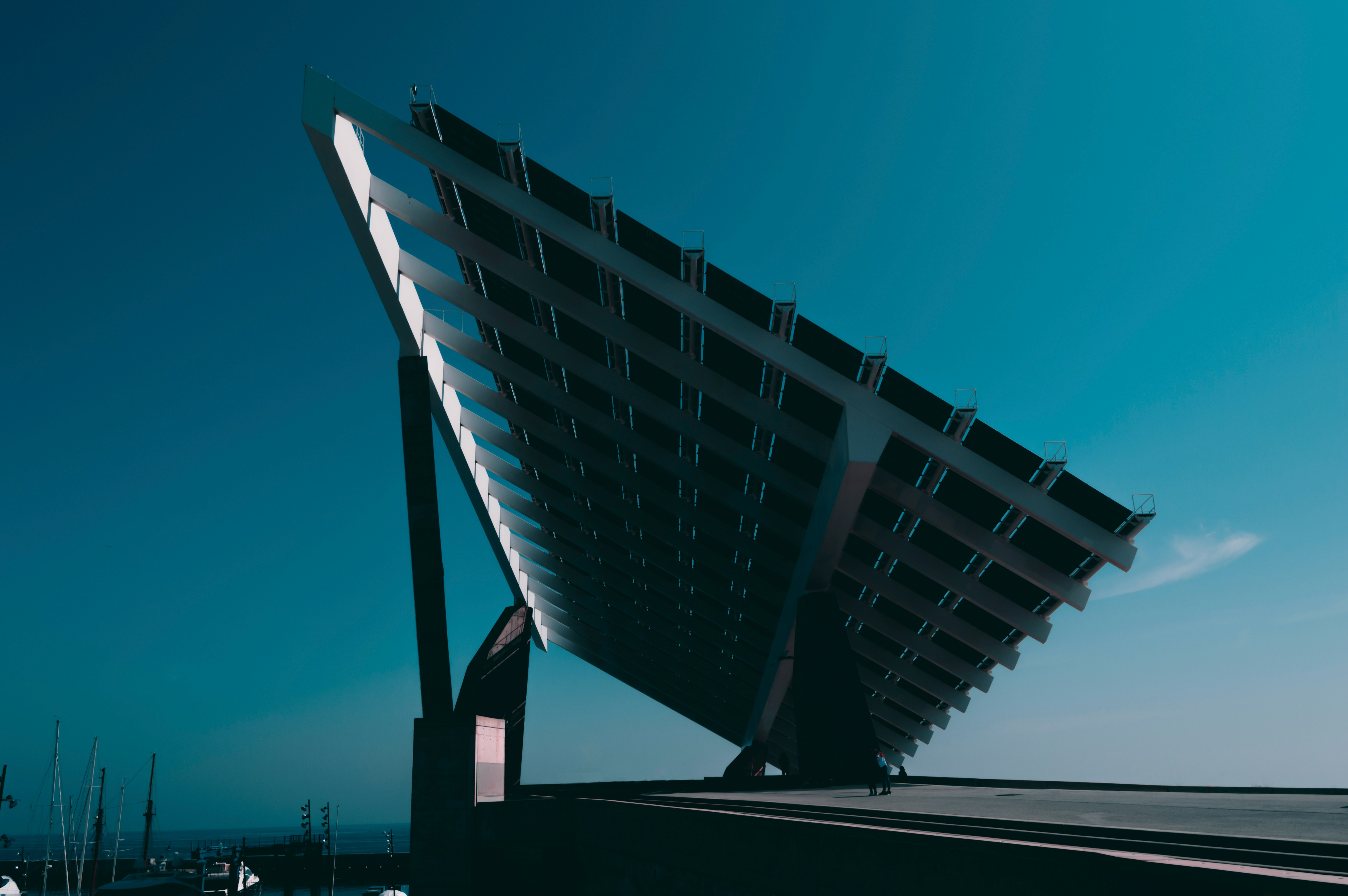

3 More Applications of Fiber Optic Spectrometers

The application of fiber optic spectrometers extends beyond semiconductors, covering fields like environmental monitoring, energy development, chemical analysis, biomedical research, and agriculture. Their broad market potential and application prospects contribute to diverse growth opportunities for the semiconductor industry.

4 Future Outlook

The application of fiber optic spectrometers in semiconductors holds profound significance and immense value. As semiconductor technology advances and market demand grows, their integration will deepen further. In the future, fiber optic spectrometers are poised to become indispensable tools in the semiconductor sector, injecting new vitality and robust momentum into the industry's development.

Post time: Nov-21-2024