Reflectors are optical devices capable of reflecting light, based on the law of reflection. When light strikes a surface, the angle of incidence equals the angle of reflection.

1. Classification by Coating

Most reflectors used in optical instruments have high-reflective coatings, metal films, or dielectric films (non-metal films). Typically, metal films' reflectivity is insensitive to the angle of incidence, while dielectric films' reflectivity is highly dependent on the angle of incidence. Hence, dielectric reflectors often specify an angle of incidence range. Some specialized dielectric coatings may have their reflectivity curves shifted.

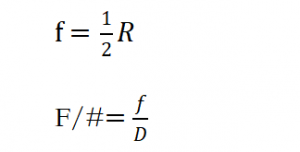

1.1 Metal Film Reflectors

Metals commonly used for coatings include aluminum, silver, and gold, which have high reflectivity in the ultraviolet, visible, and infrared ranges. A protective layer, such as silicon dioxide or magnesium fluoride, can be applied over the metal film to extend its lifespan. Below are the reflectivity curves for metal film reflectors.

1.2 Characteristics of Metal Film Reflectors

Reflectivity: Generally high, especially in the visible and near-infrared ranges.

Reflective Bandwidth: Flat characteristic curves with wide reflective bandwidth, suitable for a broad wavelength range.

Wavelength and Angle Influence: Reflectivity is minimally affected by changes in wavelength and angle of incidence, demonstrating good stability.

Mechanical Hardness: Typically low, requiring careful handling to avoid scratches or damage.

Cleanliness: Generally cannot be wiped directly and require specific cleaning methods, such as cotton swabs with organic solvents.

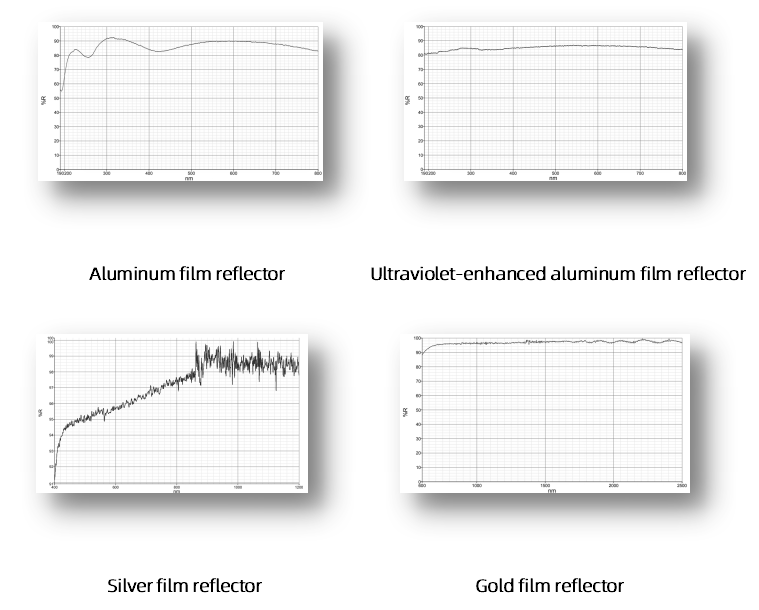

1.3 Dielectric Film Reflectors

Non-metallic coatings include single-layer or multi-layer dielectric films. Multi-layer films combine high and low refractive index materials. Dielectric reflective films have narrower spectral bandwidths than metal films but offer high reflectivity for specific wavelengths. These films are particularly useful in monochromatic systems, such as optical instruments using laser radiation. Below are the reflectivity curves for dielectric film reflectors.

1.4 Characteristics of Dielectric Film Reflectors

Reflectivity: Similarly high, with some designs approaching 100%.

Reflective Bandwidth: Narrower than metal films, often designed for specific wavelength ranges.

Wavelength and Angle Influence: Reflectivity and bandwidth are closely related to the angle of incidence and are also affected by the polarization state of the incident light, except at 0° incidence.

Mechanical Hardness: Usually higher, durable for cleaning operations, and can be wiped Cleanliness: Easier to clean and maintain compared to metal films.

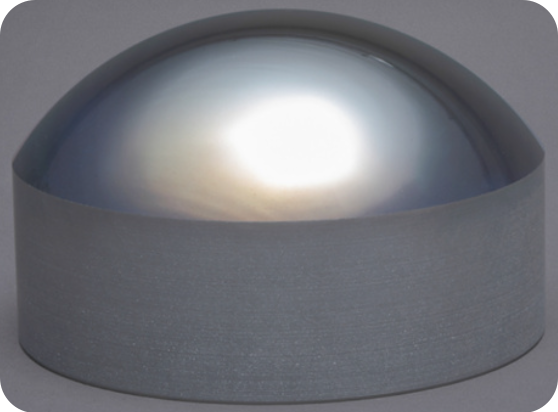

2. Classification by Surface Shape

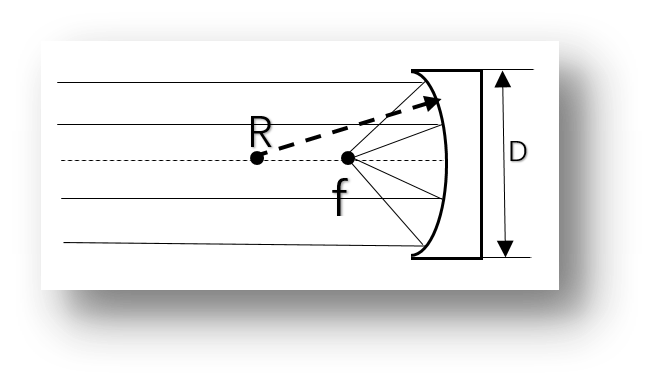

Reflectors can redirect or deflect light at a certain angle, fold an optical system into a given shape or size, provide the correct imaging orientation, laterally shift the optical axis, split or combine beam intensity or aperture at the pupil, provide dynamic beam scanning, or disperse the beam (gratings). They are classified into plane reflectors, cylindrical reflectors, spherical reflectors, and aspherical reflectors. Spherical reflectors can be further divided into concave and convex reflectors.

3. Product Recommendations

Concave metal film reflectors are generally critical components in fiber optic spectrometers. The optical design of the lens and the stability of the coating determine the spectrometer's performance. Different coatings are used for different wavelength ranges, and some specialized products may employ aspherical designs to further improve optical performance, though this can increase costs. Cost and performance considerations often need to be balanced. Beijing Jinzhitech offers high-cost-performance products and solutions, providing fiber optic spectrometers for ultraviolet, visible, and near-infrared ranges. For more details, please visit: Fiber Optic Spectrometers - JINSP Company Limited (jinsptech.com)

Post time: Jul-03-2024