With the rapid development of photoelectric sensing technology, machine vision endows AI devices with precise vision capabilities, not only refining the recognition accuracy of the shape of the object, but also relying on spectral detection technology to deeply analyze the mystery of the spectral characteristics of the object. Spectral data, a intricate map that integrates both wavelength and light intensity dimensions, is leading the wave of transformation towards industrial intelligence, medical precision, and agricultural efficiency. The improvement in the performance of spectral detectors, particularly the application of TEC technology, effectively stirs the thermal dark current noise, greatly boosting the signal-to-noise ratio. This enables the capture of weak spectral signals under low-light conditions, further expanding the boundaries and application potential of optoelectronic sensing technology.

1. Brief description of detector cooling

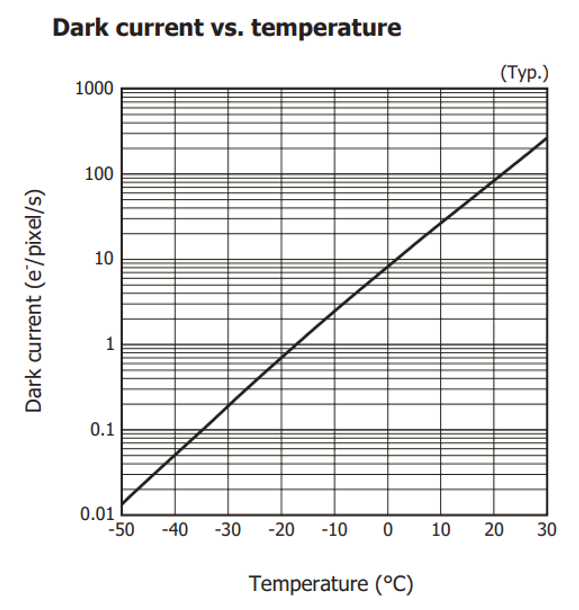

Noise is indeed one of the key parameters of the new generation of scientific research grade detectors, and the thermal dark current is one of the primary noise sources. If the dark current noise is too large, it can overwhelm the valid signals, significantly reducing the detection signal-to-noise ratio. Studies have shown that as the temperature of the optoelectronic sensing chip decreases, the thermally generated dark current exhibits an exponential decline. Therefore, refrigeration has become an effective means to suppress the thermal dark current noise.

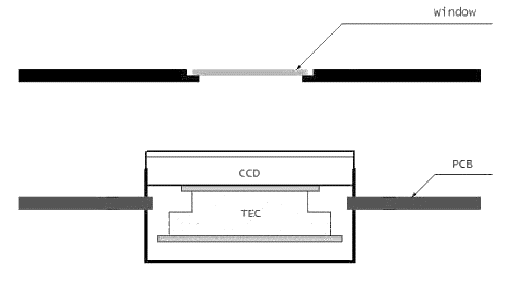

There are various methods of detector refrigeration, mainly including mechanical refrigeration, liquid nitrogen refrigeration and thermoelectric refrigeration. The mechanical refrigeration method has a large mechanical noise and requires a vacuum pump to maintain a high degree of vacuum for the detector. Liquid nitrogen refrigeration can reach extremely low temperature by using phase change principle, but its structure is complex, large volume, and maintenance is not convenient. Thermoelectric Cooler (TEC) utilizes the thermoelectric materials thermoelectric effect for refrigeration and there are advantages such as small size, no mechanical noise, high refrigeration efficiency, easy maintenance, long life. By controlling the current or voltage of TEC, Intelligent and rapid temperature control can be achieved. At present, the international refrigeration detector mainly uses TEC refrigeration technology.

2. TEC cooling principle

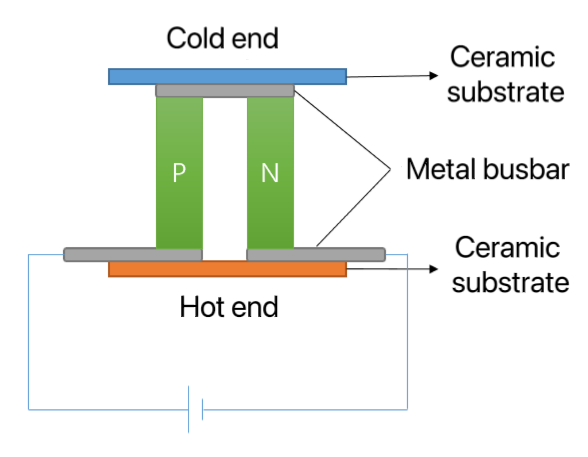

TEC refrigeration (thermoelectric refrigeration) primarily utilizes the thermoelectric effect of materials for refrigeration, which is completed by the joint action of five different effects, including Seeback effect, Peltier effect, Thomson effect, Joule effect, Fourier effect. The Paltier effect plays a leading role in refrigeration. The Paltier effect is also the inverse of the Seebeck effect. when a current follows through two different conductors, one end absorbs heat, and the other end releases heat, with the amount of heat being directly proportional to the current flowing through it. Precise temperature control can be achieved by controlling the current or the voltage at both ends. When applied to the photoelectric sensor chip, the cold end of TEC can realize the cooling control of the detector, reduce the dark current, and improve the signal-to-noise ratio. Compared with other cooling technologies, TEC has several unique advantages, such as:

● Stability and reliability: no moving parts, no vibration and noise

● Accurate temperature control: cooling speed and temperature difference can be accurately adjusted

● Efficient refrigeration: multiple levels can be superimposed to reduce the temperature to an extremely low level

● Flexible temperature control: changing the direction of the working current can switch the cooling and heating

● Integrated equipment: small size, light weight, flexible installation position, easy to integrate

3. The technological advantages of TEC

● Reduce the dark current: The dark current is the current produced by the detector in the absence of light, which increases with the temperature. By lowering the operating temperature of the detector through TEC refrigeration technology, the generation of dark current can be significantly reduced, improving the signal-to-noise ratio and sensitivity.

● Improved image quality: The reduction in dark current means the detector is able to capture sharper, purer images at long exposures or in low light environments. This is particularly important for astronomical observations, medical imaging and other fields that require high image quality.

● Extended service life: High temperatures accelerate the aging and damage process of the detector. Keeping the detector operating at a lower operating temperature through TEC refrigeration technology can extend its service life and improve its stability.

4. Product recommendation

Jinsp provides optical fiber spectrometer based on TEC refrigeration detector, scientific grade refrigeration can reach -80℃, to provide customers with high quality, high signal-to-noise ratio of spectral signals. Specific models of optical fiber spectrometer detector types are diverse and replaceable, while accepting custom needs, to provide professional and fast customization services.

Please visit the link below for details:Fiber Optic Spectrometers - JINSP Company Limited (jinsptech.com)

Post time: Jul-25-2024